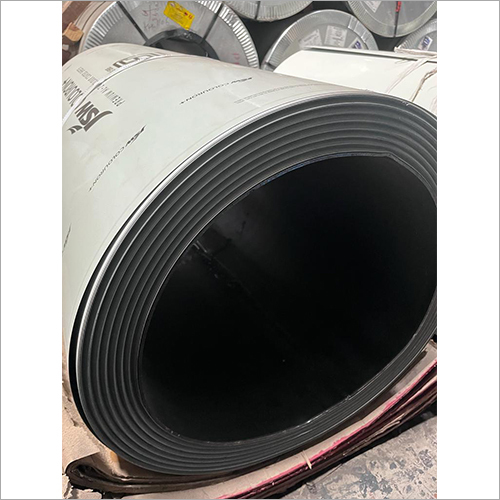

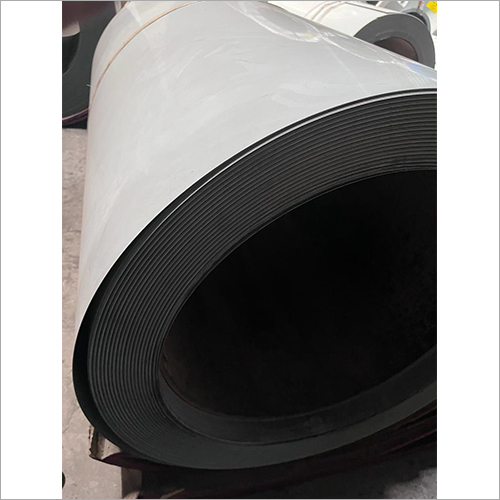

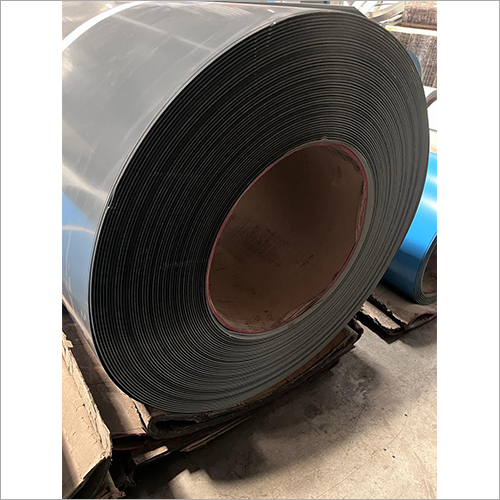

Colour Coils

MOQ : 50 Kilograms

Colour Coils Specification

- Surface Treatment

- Color Coated

- Usage

- Industrial

- Material

- Steel

- Technique

- Cold Rolled

- Product Type

- Color Coils

- Grade

- Premium

- Coil Thickness

- Standard Meter

- Color

- Black

- Hardness

- Standard

- Application

- Industrial

- Coating Type

- Polyester / Epoxy

- Coil ID

- 508mm / 610mm (standard options)

- Packing Type

- Standard Export Packaging

- Width

- Standard or as per requirements

- Rust Resistant

- Yes

- Finishing

- Smooth

- Edge

- Mill Edge / Slit Edge

Colour Coils Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 25000 Kilograms Per Month

- Delivery Time

- 1 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India, East India, West Bengal, Tamil Nadu, Arunachal Pradesh, Delhi, Haryana, Mizoram, Chandigarh, Maharashtra, Karnataka, South India, Jammu and Kashmir, Central India, Telangana, Meghalaya, Uttar Pradesh, Odisha, Daman and Diu, Assam, Goa, Himachal Pradesh, Tripura, West India, Jharkhand, , Chhattisgarh, Gujarat, Pondicherry, Bihar, Rajasthan, Madhya Pradesh, Sikkim, Andaman and Nicobar Islands, Manipur, Kerala, Uttarakhand, Lakshadweep, Punjab, Dadra and Nagar Haveli, North India, Nagaland, Andhra Pradesh

About Colour Coils

Our offered Color Coils are available in a wide range of colors & finishes. The colors are created using a variety of techniques, including painting, printing, & laminating, & can be customized to suit the specific needs of a project. The coils are used for roofing & siding applications, as they offer a durable, weather-resistant finish that can withstand exposure to the elements. Color Coils are widely used in the manufacturing of automotive parts, appliances, & other products that require a durable & colored finish.

Premium Colour Coils for Industrial Excellence

Offering versatility in dimensions, our steel colour coils meet diverse industrial needs. With smooth finishing and customizable widths, they are tailored to match client specifications. The robust surface treatment using premium coatings like polyester or epoxy ensures lasting performance in demanding environments.

Superior Protection & Durability

Designed for resilience, these coils are rust-resistant and possess excellent surface hardness. The high-quality color coating not only adds aesthetic appeal but also extends the lifespan of the steel, making them suitable for long-term industrial use in harsh conditions.

FAQs of Colour Coils:

Q: How are your colour coils manufactured to ensure durability and rust resistance?

A: Our colour coils are made from premium-grade cold-rolled steel, treated with advanced surface treatments and specialized coatings like polyester or epoxy. This process guarantees superior rust resistance and overall durability to withstand tough industrial environments.Q: What are the customization options available for coil dimensions and weight?

A: We offer tailored solutions to meet your specific requirements regarding coil length and weight. Standard widths and thicknesses are available, but we can adjust these parameters as per individual project needs.Q: When is it suitable to use these colour coils in industrial applications?

A: These colour coils are best utilized in industrial settings requiring robust steel products with enhanced surface protection, such as construction, fabrication, and manufacturing sectors.Q: Where are your colour coils manufactured and supplied from?

A: All our colour coils are manufactured and dispatched from our advanced facilities in India, ensuring reliable and timely supply to industrial clients nationwide.Q: What is the standard process for surface treatment on these coils?

A: Each coil undergoes a thorough color coating process using either polyester or epoxy paints, applied over the cold-rolled steel substrate to deliver a smooth, black, and highly protective surface.Q: How should colour coils be handled and stored after delivery?

A: Our coils come in robust, standard export packaging for safe transit. For best results, store them in dry, clean environments and handle with appropriate equipment to prevent surface damage during unloading and installation.Q: What are the primary benefits of using your colour coated coils for industrial purposes?

A: The main advantages include exceptional rust resistance, extended product life, customizable size options, and a premium finish, enabling industries to achieve efficient, long-lasting, and visually appealing results in their applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS